P3000 Boiler Tube Expanders

Uses: P3000 Boiler Tube Expanders

P3000 boiler tube expanders when used on thick tube sheets are adjustable to 5.3/8″. There are two different model ranges based on tube sheet thickness. First from 1/2″ to 4.3/8″. Then secondly from 1.1/2″ to 5.3/8″. The tube OD ranges from 1.1/4″ OD to 4.1/2″OD. If requiring larger sizes please contact us directly. However, if used in mud and steam drums then the tube end is usually flared. For example, the P3000 boiler tube expanders would be step-rolled to cover the thickness of the drum. Whereas the P-1000 would finish the roll and flare the end at a total of 30 degrees.

The drum mandrel is the standard mandrel. This is the mandrel always supplied. All Powermaster Industrial expanders when shipped include the mandrel. Furthermore, if requiring short-series mandrels please consult the pdf for part numbers.

See pdf for details and specifications:

Tube Hole Serration/Grooving

As seen above, the holes in this drum have been serrated/grooved. This machining adds strength to the rolled joint by thinning the wall thickness and compressing it into the grooves. This is mainly found in medium to high-pressure boilers.

Consult the link below for information on Serrating/Grooving Tools

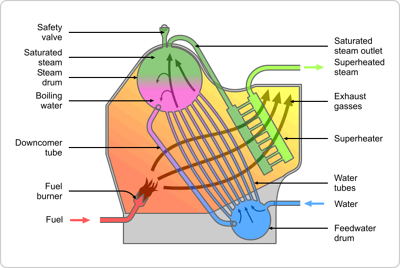

The diagram above shows the details of a steam boiler with added superheater. The steam drum, located at the top of the unit with the mud drum or feed water drum at the bottom. Water tubes are between the two drums. Saturated steam leaves the steam drum and onward to the superheater.

Electric Tube Rolling Motors

PTR-03

The PTR-03 Electric Rolling Motor, crafted and engineered in Germany, stands as a robust and resilient powerhouse. Its exceptional performance has made it a leading choice across various applications. From rigorous drilling to precise line boring, the Eibenstock motor series caters to the demands of continuous power in engineering. With options available in 120-volt or 240-volt variants and a frequency range of 50-60 Hertz, we offer the ideal drive model tailored to your specific power supply. Trust us to deliver the utmost performance when it comes to rolling boiler tubes.

The unit boasts a formidable power output, generating high torque capable of rolling 3 OD tubes. As a result, it is an ideal machine for the pulp and paper industry. Equipped with a gradual startup feature, it offers two gears with a load speed ranging from 30-75/90-230 RPM. Additionally, a simple switch enables the drive motor to effortlessly reverse expanders out of the tube. The PTR-03’s arbor is a Morse taper 3, allowing for seamless connection to the expander. To cater to your specific requirements, we provide a mandrel drive, available in either a ¾ or 1.0 female square option.

Always in Stock.

Product Quality

We work to high tolerances for all machining of expanders and associated equipment. This allows accurate expansion to achieve perfect sealed joints in tube sheets. Using the best tool steel and cryogenic processes for hardening and conditioning. Giving our tooling the optimum performance in the harshest surroundings. We assemble each expander while checking the quality of the manufacture. Every individual tool is laser-marked with our name, Powermaster Canada. Also, we mark with the tube OD, wall thickness and expansion range. Expanders are then oiled bagged and boxed for shipping. Therefore, with our quality control and machining excellence, we supply a quality tool.

Fundamentals of the Grooving Tool

Grooving and serrating tools are for putting grooves within the tube sheet hole. This then produces a better and stronger seal once the tube is rolled in the sheet. Two different models are available covering from 3/8″ to 4/0″ bore size.

These tools when designed, were for ease of use, ensuring precise and clean groove cuts. They connect to the drive unit via Morse Taper, ranging from MT2 to MT5 for larger tube holes.

Follow the link below to the Grooving/Serrating Page.