Grooving and Serrating Tools

Fundamentals of the Grooving Tool

Grooving and serrating tools are for putting grooves within the tube sheet hole. This then produces a better and stronger seal once the tube is rolled in the sheet. Two different models are available covering from 3/8″ to 4/0″ bore size. These tools are designed with the operator in mind to achieve the cleanest and most accurate groove cutting. Connection to the drive unit is by Morse Taper from MT2 to MT5 for the very large tube holes.

Models of Grooving and Serrating Tools

ST Series

We manufacture 10 models covering from 3/8″ to 2.1/2″tube OD. Also available in mm sizing. These tools are high production tools which work well in a CNC environment. Made from top-quality steel alloy and one piece cryogenically treated to ensure maximum life is achieved.

Standard tool bit spacing for grooves is 1/8×3/8×1/8 or 1/8×1/4×1/8 and specific spacing can be produced.

NW Series

We manufacture 4 models covering from 3/8″ to 4.0″ tube OD. Also available in mm sizing. These tools have a range in size that they can cover by changing the pilot Nose and Cutter. Simple adjustment changes the depth and configuration. Can be used in CNC drilling machines, lathes and boring machines.

Standard tool bit spacing for grooves is 1/8×3/8×1/8 or 1/8×1/4×1/8 and specific spacing can be produced. The life of the cutting bit can be extended by resharpening.

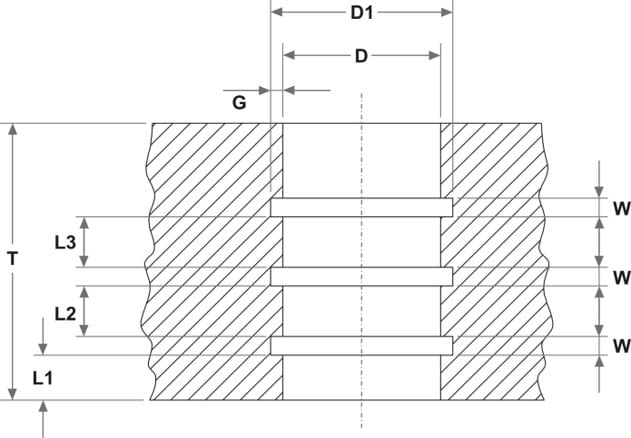

Groove Configuration

When inquiring about the two models of grooving and serrating tools please supply the following data:

- D = Hole Diameter.

- D1= D + (Gx2).

- G = Depth of Groove.

- L1 = Distance to 1st Groove.

- L2 = Distance between Groove 1 and 2.

- L3 = Distance between Groove 2 and 3.

- W = Width of Groove.

- T = Thickness of Tube Sheet.

- Identify the type of the Tube Sheet Material.