Introduction to the Rolling Boiler Tubes

Commercial and industrial boilers offer numerous advantages for businesses. They are built to be more durable, requiring less maintenance and lasting longer. They have been proven to be more energy-efficient and reliable compared to residential boilers. These boilers are also customizable to cater to the unique requirements of a business. They can generate a significant amount of hot water or steam, making them perfect for businesses that require a steady supply of power. Moreover, commercial boilers can aid businesses in lowering their carbon footprint, thereby enhancing their environmental impact.

This page guides those seeking the procedures for removal, replacement and rolling boiler tubes. It applies to boilers, heat exchangers, condensers, and oil coolers. These processes can be quite labour-intensive. Tube removal often accounts for over 75% of the total labour cost. To succeed, you must understand how to remove and replace tubes. The task at hand involves cutting, pulling, and rigging tubes. Additionally, we will also cover repair techniques such as tube plugging and sleeving. This page aims to provide useful information on tube-related procedures. This information will help you complete your project. It is useful for contractors, engineers, and technicians.

Types of Tubing

Difference Between ERW and DOM tube

ERW (Electric Resistance Welded)

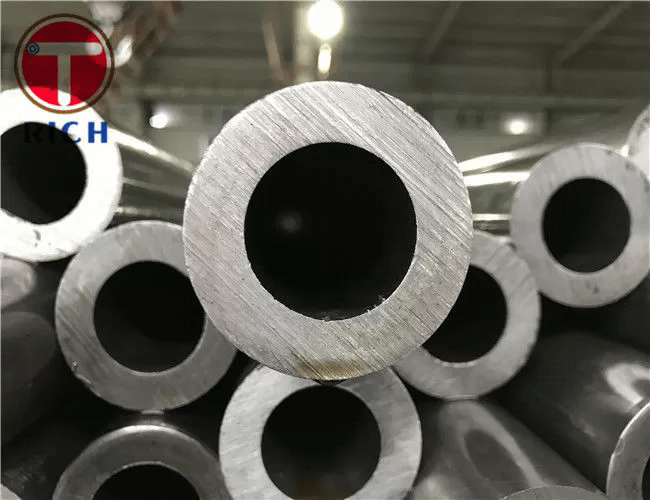

The nomenclature ERW refers to a specific type of welding process. Involving both spot and seam welding. Seam welding, used during the manufacturing of round, square and rectangular steel tubing. The steel strip is first uncoiled and is side-trimmed to control width. Furthermore, conditioning of the edges for welding takes place. The strip then passes through a series of contoured rollers. At the same time cold-form the material into a circular (square or rectangular) shape. The edges, forced together under pressure, form a butt joint. After forming the joints are then welded.

Meanwhile, by heating the material to above 2000° F, the joint becomes complete. The flash weld that has formed is now removed from the outside diameter of the tube. Once testing is complete, the tube then passes through a series of sizing rolls. This final process attains its precise finished size. Afterwards, the tube is then straightened and cut to length.

The material used in the manufacturing process is SAE 1010 or its equal. This product is available in Cold Rolled steel (CREW) for 0.060” wall and lighter. Hot Rolled steel (HREW) for 0.083” wall and heavier. Removing the flash weld inside the tube is a necessity for boiler tube.

Logistics to be Considered

Logistics need to come into play. Manpower considerations to complete on time and within budget are critical. Experienced lead hands in all aspects of tube removal and rolling boiler tubes. You need to confirm what power, pneumatic or electric is available. What are the boiler room burning and welding procedures? Level of third-party liability required. Availability of the new tubes, tube OD and BWG and lead time to get them on-site. In a sub-basement, do we need confined space procedures in place? Confirm welder's qualifications are up to date. Who will be shutting down the boiler? Who supplies the technician for this? Confirmation with the stationary/steam engineer will confirm who has this responsibility.

Tooling

Availability of specialized tooling. To buy or to rent can be lead times of up to six weeks. This is why we carry all standard boiler tube expanders in stock. Consider rental of the rolling motors unless you intend to continue "R" Stamp work. Powermaster Industrial rents rolling motors, electric and pneumatic. If you need to order, see the Links below. The same applies to the rental of pullers and rolling motors.

DOM (Drawn Over Mandrel)

DOM is not a type of steel tube, but rather the process for finishing the tube. A high-quality tube constructed from SAE 1020 or 1026 steel or their equal. Meanwhile, the first stages of manufacturing are identical to ERW. Yet, in the finishing stages, the tube is cold-drawn over a mandrel. Thus, the cold-drawn process provides the tube with better dimensional tolerances. Finally, improved surface finish and stronger weld strength are achievable. DOM is often referenced as a “seamless tube”. When it does have a seam (although it is almost invisible).

Removal of Tubes

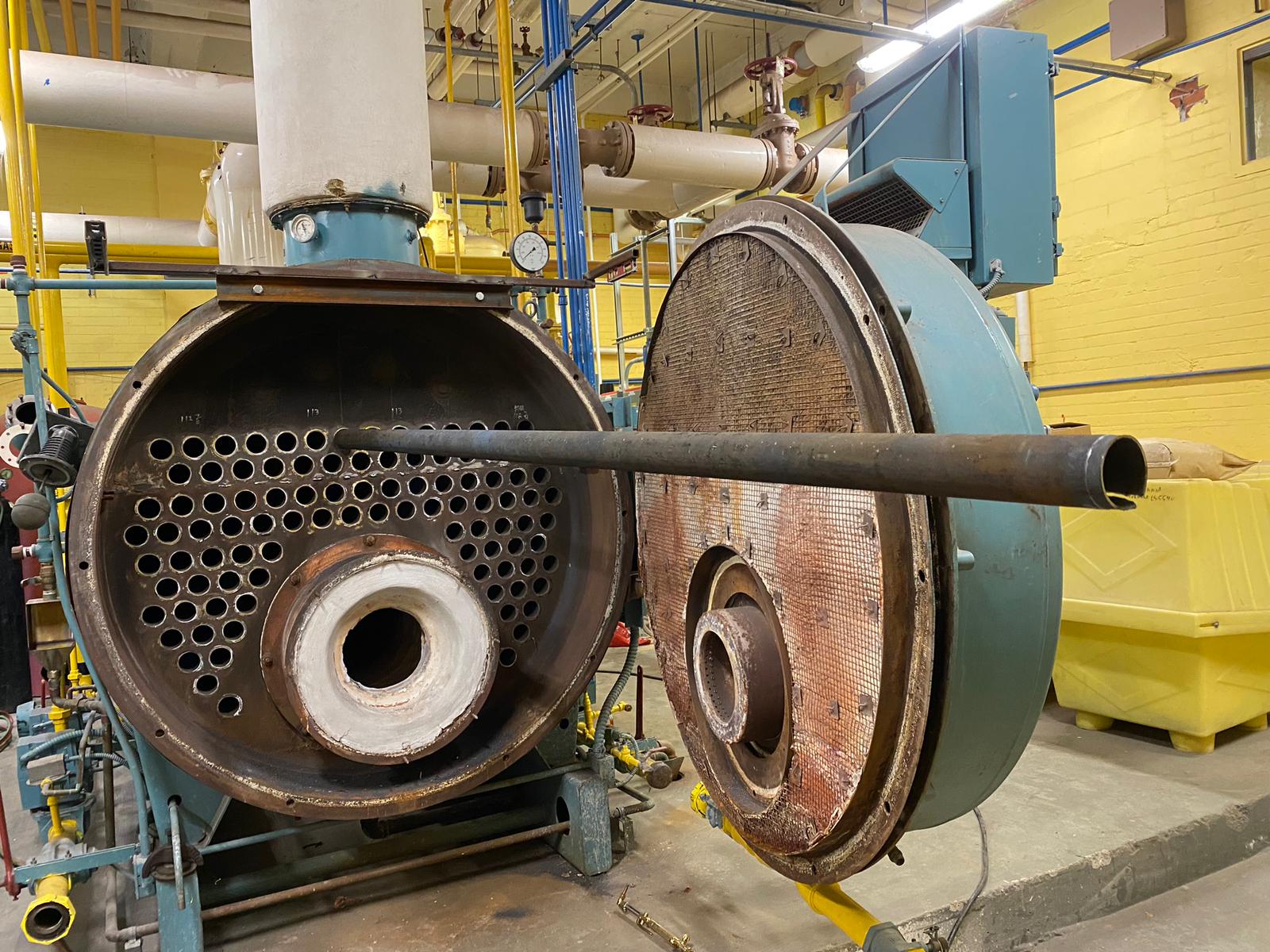

Fire Tube Boilers

Removing tubes from a pressure vessel is a complex procedure that should be governed by various factors. One of the significant factors that have an impact on this process is water treatment. The formation of scale or mineral deposits on the outer surface of the tube can make the removal process difficult. When the tubes are free of scale, they can be released with ease after the seal roll at each end is removed. This is why water treatment is crucial for ensuring that the tube removal process is smooth. Proper maintenance and cleaning of pressure vessels are also essential to ensure that the tubes do not become prone to scaling and other issues that could make them challenging to remove. By prioritizing water treatment and other maintenance measures, pressure vessel operators can help to ensure that the removal of tubes from these vessels can be performed safely and efficiently.

Different Ways of Removing Boiler Tubes

Spear pulling involves using a spear or stud that is inserted into the tube and then pulled out with a hydraulic or pneumatic jack. This method is commonly used for smaller tubes or tubes that are not heavily welded or expanded.

Knockout tools can be used for tubes that have been expanded into the tube sheet. These tools use a mechanical or hydraulic force to knock the tube out of the tube sheet. This method is often faster and more efficient for larger tubes or tubes that are heavily expanded.

Torching involves cutting the tube using a torch or plasma cutter. This method is commonly used for tubes that are heavily welded or difficult to remove through other means. However, torching can be time consuming and may require additional steps to remove the remaining tube stub from the tube sheet.

Induction heating is another method that can be used to remove tubes. This involves using an induction coil to heat the tube and then using a hydraulic or mechanical force to push or pull the tube out. This method is often used for tubes that are difficult to access or remove through other methods.

It is important to note that the specific method used for tube removal will depend on several factors, such as the size and type of tube, the condition of the tube and tube sheet, and the available equipment and resources. It is recommended to consult with a professional or experienced technician when attempting to remove boiler tubes to ensure the process is done safely and efficiently.

Boiler Tubes - Formulae to work out a Finished ID.

Rolling boiler tubes is the art of reducing a tube wall by compressing the OD of the tube against a fixed container, therefore boiler tubes into a tube sheet. To achieve a proper tube joint, causing a gas-tight seal. The tube wall must be reduced by a predetermined percentage. The chart below can help determine the correct tube wall reduction needed in tube rolling.

This Chart shows a typical 2.0"OD x 10 BWG (0.134")

Principals of Rolling Boiler Tubes - Determine the following:

- (A) Determine the Hole size.

- (B) Determine the tube outside diameter.

- (C) Subtract the tube outside diameter from the tube hole dimension.

- (D) Accurately measure the ID of the tube before rolling.

- (E) Add the dimension found in “D” to the clearance between the tube OD and the tube hole, you will then know the tube’s inside diameter at metal to metal contact.

- (F) Roll the tube to what you feel is a good tube joint. This example was rolled and then the ID of the tube was checked with the tube gauge.

- (G) By subtracting “E” from the rolled diameter you determine the actual amount of expansion (tube wall reduction) on the inside diameter of the tube. This can be converted to a % of wall reduction by dividing the actual wall thickness (“B minus D”) in the amount of the roll.

Follow the link above for Expander specifications found in individual pdf's for Rolling Boiler Tubes

Tube Sheet Hole

Tube Outer Diameter OD

Clearance (A-B)

Tube Inner Diameter ID

Clearance

Inner Diameter at Metal to Metal

13% of 0.134 x 2

Inner Diameter at Metal to Metal

Expanded Tube Inner Diameter

2.010″

2.000″

0.010″

1.732″

+0.010″

1.742″

0.035″

1.742″

1.777″

Tube Wall Reduction Percentages based on Material

Application

Non Ferrous tubes in surface condensers.

Steel tubes in heat exchangers.

Soft Copper, Cupro Nickel and aluminum tubes in heat exchangers.

Boiler tubes.

Tube Wall Reduction

3% to 4%

5% to 10%

8% to 12%

12% to 14%

Major Causes of Tube Leaks

Tube rolling leakage can happen because of: under rolling, over rolling, improper preparation of tube sheets and differential thermal expansion. Improper expansion can lead to serious difficulties with the manufacturer and the repair serviceman.

Under Rolling

Under rolling is when the tube is not expanded to fill the tube sheet hole and the proper amount of wall reduction is not obtained. It is better to under roll than to over roll.

Over Rolling

Over rolling is when the expansion of the inside diameter of the tube surpasses the expansion required for the proper percentage of wall reduction for the ultimate tube joint. This can do considerable damage a tubular vessel. Excessive rolling will decrease the dimensions of the ligament between tube holes and weaken the bridge. Once a ligament is weakened, it will cause a reaction in all ligaments surrounding that weak ligament. If we decrease the strength of the ligament the tube to the tube being rolled will be weak.

Also, it causes distortion in tube sheets or drums, such as egg-shaped holes. It will also cause diametrical expansion which is the overall increase of the tube sheet or drum. Over rolling has also been known to cause a tube sheet to bow or warp to the point where the standard length tube could not be used in the vessel until bowing or warpage is returned to normal. This is usually corrected by placing stay rods in the vessel and pulling the tube sheets back to their original position.

Preparation of Tube Sheets

Preparation of tube seats in drums, tube sheets, and headers is as follows: Tube holes are normally drilled and reamed to approximately 1/32” larger than the nominal outside diameter of the tubes. It is extremely important during this operation that there are no longitudinal scorings left in the tube seat. In cases where out-of-roundness is extreme, predrilling of the tube is advised. Be certain that the tube hole walls and the grooves in the tube walls are cleaned down to bare metal before the tubes are inserted. Be certain all foreign material such as oil, grease rust or just plain dirt is removed. Special attention during this cleaning will prevent serious trouble later.

After tube holes have been prepared they are usually coated with a rust preventative compound. Before inserting any tube, it is important to remove all traces of this coating. It is extremely important that great care be taken in handling the tubes for insertion in all of the vessels discussed above. Be certain that the tube ends are clear of any foreign material. Be especially certain that there are no chips on the tubing which may gouge the tube sheet or tube seat when the tube is placed in the vessel.

In some cases, it will be necessary to force a tube into a tube hole. This should be done with extreme care. It is better to spring the tube than to try to force it with a hammer. If a tube end is kinked or damaged before rolling, the expanded end will be damaged, and a leaky roll joint will result. Attention at this time to the tube ends and the tube alignment will prevent future troubles.

Tube Wall Reduction Percentages based on Material

Application

Non Ferrous tubes in surface condensers.

Steel tubes in heat exchangers.

Soft Copper, Cupro Nickel and aluminum tubes in heat exchangers.

Boiler tubes.

Tube Wall Reduction

3% to 4%

5% to 10%

8% to 12%

12% to 14%

Major Causes of Tube Leaks

Tube rolling leakage can happen because of: under rolling, over rolling, improper preparation of tube sheets and differential thermal expansion. Improper expansion can lead to serious difficulties with the manufacturer and the repair serviceman.

Under Rolling

Under rolling is when the tube is not expanded to fill the tube sheet hole and the proper amount of wall reduction is not obtained. It is better to under roll than to over roll.

Over Rolling

Over rolling is when the expansion of the inside diameter of the tube surpasses the expansion required for the proper percentage of wall reduction for the ultimate tube joint. This can do considerable damage a tubular vessel. Excessive rolling will decrease the dimensions of the ligament between tube holes and weaken the bridge. Once a ligament is weakened, it will cause a reaction in all ligaments surrounding that weak ligament. If we decrease the strength of the ligament the tube to the tube being rolled will be weak.

Also, it causes distortion in tube sheets or drums, such as egg-shaped holes. It will also cause diametrical expansion which is the overall increase of the tube sheet or drum. Over rolling has also been known to cause a tube sheet to bow or warp to the point where the standard length tube could not be used in the vessel until bowing or warpage is returned to normal. This is usually corrected by placing stay rods in the vessel and pulling the tube sheets back to their original position.

Preparation of Tube Sheets

Preparation of tube seats in drums, tube sheets, and headers is as follows: Tube holes are normally drilled and reamed to approximately 1/32” larger than the nominal outside diameter of the tubes. It is extremely important during this operation that there are no longitudinal scorings left in the tube seat. In cases where out-of-roundness is extreme, predrilling of the tube is advised. Be certain that the tube hole walls and the grooves in the tube walls are cleaned down to bare metal before the tubes are inserted. Be certain all foreign material such as oil, grease rust or just plain dirt is removed. Special attention during this cleaning will prevent serious trouble later.

After tube holes have been prepared they are usually coated with a rust preventative compound. Before inserting any tube, it is important to remove all traces of this coating. It is extremely important that great care be taken in handling the tubes for insertion in all of the vessels discussed above. Be certain that the tube ends are clear of any foreign material. Be especially certain that there are no chips on the tubing which may gouge the tube sheet or tube seat when the tube is placed in the vessel.

In some cases, it will be necessary to force a tube into a tube hole. This should be done with extreme care. It is better to spring the tube than to try to force it with a hammer. If a tube end is kinked or damaged before rolling, the expanded end will be damaged, and a leaky roll joint will result. Attention at this time to the tube ends and the tube alignment will prevent future troubles.

Improper Preparation of Tube Holes

Improper preparation of tube holes is another major cause of tube leakage. If the tube sheet or drum is gouged, it is extremely hard to expand the tube to fill these gouges or tears without over-rolling. The smoother the tube seat or tube hole the easier it is to roll an optimum tube joint. The ligaments and light tube walls make it more important that the finish of the tube hole be in the low micro range. We find many manufacturers today are drilling, reaming and sizing or burnishing to get the micro finish desired for tube holes.

Preparation of Tube Holes

The preparation of tube holes in heat exchangers and condensers is as follows. Drill and ream tube sheet holes to .007” to .010” over the outside diameter of the tube to be used. Be certain the ligaments are enough to guarantee a safe and permanent tube joint. When conditions permit, utilize a sizing or burnishing tool to further assure a good finish in the tube hole. This will also increase the tensile strength of the ligament. The serrations or grooves to be used will determine the holding power of the tube. It is extremely important when retubing that the grooves be cleared of all metals or any foreign material.