New - Tube Sheet Hole Reamers

Tube sheet hole reamers provide a machined finish to tube sheet holes. Reaming is a machining operation in which a rotary tool takes a light cut to improve the accuracy of the round hole and reduce the roughness of the hole surface. The finished size meets the necessary specifications for tube expansion and wall thinning. It is recommended to ream the tube holes in the tube sheet to ensure the precision of the finished size. Our standard reamers feature a Morse Taper and come in three different flute lengths.

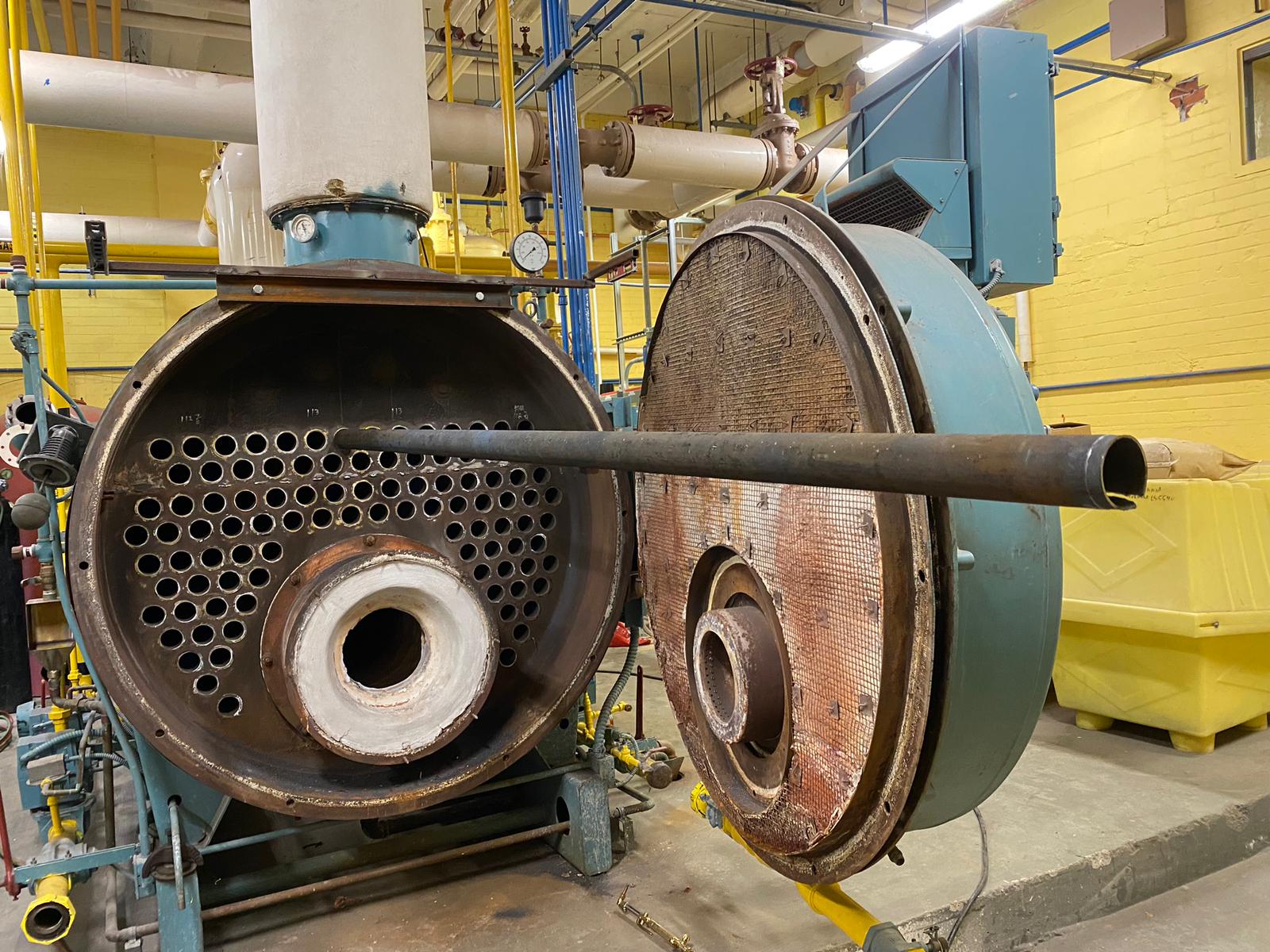

Tube Sheet Holes Reamed then Grooved

The above picture shows tube sheet holes reamed and serrated/grooved for added joint strength. This was exceptionally challenging as the material was the exotic alloy Hasteloy. The material size was 1.1/2OD tubes and the tube sheet was also 1.1/2″ thick.

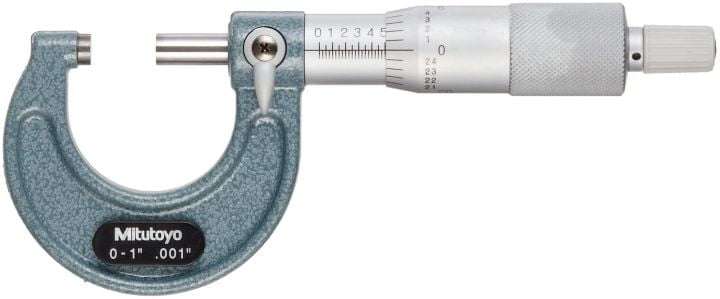

Tool Quality

We maintain high tolerances for all machining processes of expanders and related equipment, ensuring accurate expansion for perfect sealed joints in tube sheets. We utilize top-grade tool steel and cryogenic hardening and conditioning processes to enhance our tooling’s performance in the most demanding environments. Each expander is assembled with a meticulous quality check. Every tool is laser-engraved with our brand, Powermaster Canada, along with the tube’s outer diameter, wall thickness, and expansion range. The expanders are then oiled, bagged, and boxed for dispatch. Our commitment to quality control and machining precision means we consistently deliver superior tools.

Tube Sheet Hole Reamers used during re-tubes

When tubes are extracted from certain types of pressure vessels, they can become damaged. As an old tube is removed through the tube sheet, it may leave deep scratches in the tube hole. These scratches, running parallel to the tube, could allow liquids or gases to leak under pressure. Therefore, it’s necessary to ream these holes to a perfect machine finish prior to rolling.

Additionally, when tubes are re-rolled, for instance, tightened up after a leak, the ligatures between the tube holes may become damaged if excessive torque is applied during the rolling process. This can lead to the holes becoming “out of round.” Therefore, employing a reamer can eliminate the ovality in the holes.

Power Source for Reamers

PTR-03

The Electric Rolling Motor PTR-03 is a powerful, durable and hard-working drive which can be used with tube sheet hole reamers. Designed and manufactured in Germany, this drive motor has been the front-runner in many different scenarios. From heavy-duty drilling to line boring, the Eibenstock range of motors covers all aspects of engineering when continuous power is needed. Available in either 120 volts or 240 volts and with a Hertz range of 50-60. So, wherever you need power we can provide the correct drive model suited to your supply current.

The unit features high torque producing power enough to roll 3” OD tubes. Therefore, a machine which is well suited to the pulp and paper industry. With the slow start facility, it has two gears with a load speed of 30-75/90-230 RPM. And, with a change of a switch the drive motor reverses expanders out of the tube with ease. The arbor of the PTR-03 is a Morse Taper 3 therefore, to make the connection to the expander we supply a mandrel drive according to your needs. This would then be either a ¾” or 1.0” female square.

When you receive your new PTR-03, you will find it comes with a long reaction bar which we suggest is always used due to its sheer power, especially when using large tube sheet hole reamers. Also, a Morse Taper drift key and the proper operating manual. How reliable we have found this machine we never have had much call for spares. However, if the need should arise, all spares are readily available.