Fundamentals of the Grooving Tool

Grooving and serrating tools are used to create grooves inside the tube sheet holes, resulting in a stronger seal when the tube is rolled into the sheet. There are two models available, accommodating bore sizes from 3/8″ to 4/0″. These tools are engineered for ease of use, ensuring precise and clean groove cuts. They connect to the drive unit via Morse Taper, ranging from MT2 to MT5 for larger tube holes.

Models of Grooving and Serrating Tools

ST Series

Our product line includes 10 models of grooving and serrating tools ranging from 3/8″ to 2.1/2″ in tube OD, also available in millimeter sizing. These are high-production tools, ideal for CNC environments. Constructed from premium steel alloy and cryogenically treated as a single piece, they are designed to ensure maximum durability.

Standard tool bit spacing for grooves is 1/8″ x 3/8″ x 1/8″ or 1/8″ x 1/4″ x 1/8″, with custom spacing available upon request.

NW Series

Our grooving and serrating tools in the NW line include four models that accommodate tube outer diameters ranging from 3/8″ to 4.0″, with millimetre sizing also available. These tools are versatile, covering a range of sizes by interchanging the pilot nose and cutter. Adjustments are straightforward, altering both depth and configuration. They are compatible with CNC drilling machines, lathes, and boring machines.

The standard spacing for tool bits in grooves is either 1/8×3/8×1/8 or 1/8×1/4×1/8, and custom spacings are available upon request. Additionally, the lifespan of the cutting bits can be prolonged through resharpening.

Power to Drive

PTR-03

The Electric Rolling Motor PTR-03 is a robust, efficient, and industrious drive, engineered and produced in Germany. This motor has led the way in various applications, from intensive drilling to precise line boring. The Eibenstock motors cater to all engineering needs that demand uninterrupted power. They are available in 120 or 240 volts, with a frequency range of 50-60 Hertz, ensuring the right drive model for your power requirements.

This unit boasts a high torque capacity, capable of rolling 3” OD tubes, making it ideal for the pulp and paper industry. It features a slow start mechanism and two gear settings, with load speeds ranging from 30-75 to 90-230 RPM. A simple switch allows the drive motor to reverse the expanders out of tubes effortlessly. The PTR-03’s arbor is a Morse taper 3, and we provide a mandrel drive tailored to your needs, available in either a ¾” or 1.0” female square.

Upon delivery of your new PTR-03, you’ll discover it includes a lengthy reaction bar, recommended for use due to the motor’s significant power. Additionally, it comes with a Morse taper drift key and a comprehensive operating manual. The machine’s reliability is such that there is seldom a need for spare parts. Nevertheless, should the occasion arise, all spare parts are readily obtainable.

Product Quality

We maintain high tolerances for all machining processes of expanders and related equipment, ensuring accurate expansion for perfect sealed joints in tube sheets. We utilize top-grade tool steel and cryogenic hardening and conditioning processes to enhance our tooling’s performance in the most demanding environments.

Each expander or associated tool, is assembled with a meticulous quality check. Every tool is laser-engraved with our brand, Powermaster Canada, along with the tube’s outer diameter, wall thickness, and expansion range. The expanders are then oiled, bagged, and boxed for dispatch.

Our commitment to quality control and machining precision means we consistently deliver superior grooving and serrating tools.

Information we need when ordering.

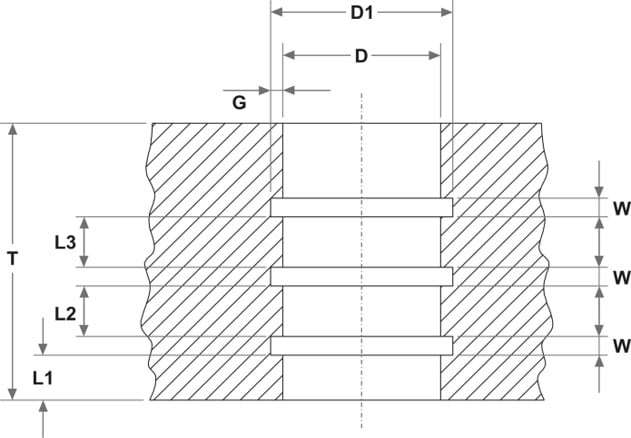

To order grooving and serrating tools, it is essential to know specific values to ensure the correct dimensions of the cutting bit are provided.

- D. Bore Diameter after reaming with tolerances.

- T. Tube Plate thickness.

- L1. Distance of the first groove.

- N. Total number of grooves.

- L2 L3. Spacing of grooves.

- W. Groove width.

- D1. Diameter of grooves.

- G. Groove undercut depth.