Combination Beading Expanders

Tube Expanding and Beading in one operation

The Powermaster Combination Beading Expander is one of the most useful and time-saving tools available. These expanders, compared to the beading method with beading chisels, save so much time they can pay for themselves in one full retube.

Beading Chisel Method:

1. Roll tube into tube sheet.

2. Bead tube to tube sheet with Air gun.

3. Re-roll tube.

Combination Beading Method:

- Roll and bead the tube into the tube sheet in one operation.

Why we Bead Tubes

We bead tubes for one reason, chiefly to transfer the heat from the tube end into the tube sheet. At first, the tube end heats during start up. Therefore, with the tube beaded back, and touching the tube sheet. The heat transfers to the larger mass, albeit the tube sheet. With this in mind, constant checking that tubes are touching the sheet is required.

Theory of Operation for the Combination Beading Expander

The combination beading expander simultaneously expands and beads the tube end in a single operation. Therefore, operating as it does, the tool assures the creations of a joint. This then is both pressure tight and has a bead in intimate contact with the tube sheet. The tool achieves this objective by the natural feed force built into the expander to force the beading roller against the end of the tube while expansion is taking place.

The ability of the tool to satisfactorily accomplish this depends upon the amount of tractive force available being of enough magnitude to enable feeding forces to be developed which will enable the beading roll to deform the end of the tube and press the bead tightly against the sheet. The tractive force is made a maximum by utilizing five expansion rolls in place of the three or four normally found in combination beading expander of this type and using coolant, which has the quality of minimum lubricity. If the beading roller expander is set so full expansion is accomplished before the bead has been formed, it will not be possible to complete a proper bead without further expansion of the tube.

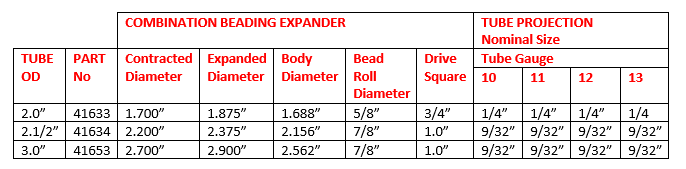

Tube Projection for the Combination Beading Expander

As can be seen above, tube projection from the tube sheet is one of the most important things to achieve the perfect bead. This projection is the material which forms the bead within the beading roll. Beware of different tube lengths required to achieve the individual tube projection. Especially on older boilers be aware of tube sheets that may have bowed or warped. Measure each distance on each tube from the outside of each tube sheet then add the projection twice if being beaded on both ends. Tube projection is from 1/4” to 9/32” depending on tube OD and wall thickness.

Our Tube Rolling Drives are one of the best forms of drive for these combination tube expanders.